For installation, please refer to the official 3DVERKSTAN instructions, as its installation is a bit more involved. If you have the Live Z adjust value set incorrectly, or if your PINDA sensor is not set to a correct distance and the nozzle hits the removable steel sheet, the nozzle may crack. Even though the ruby gemstone is highly wear-resistant, it’s also brittle. Since it is mostly made of brass, it retains the excellent heat conductivity and throughput of the stock brass nozzle, but with a very hard gemstone as its tip. Similar to the hardened steel nozzle, The Olsson Ruby is designed to print highly abrasive materials.

If you don't have the words "0.25 nozzle", "0.6 nozzle" or "0.8 nozzle" in the profile's name ( green square), the preset is for a 0.4 mm nozzle.Į3D, a UK-based company, that supplies hotends for the Original Prusa i3 printers, has a whole ecosystem of upgrades and add-ons.

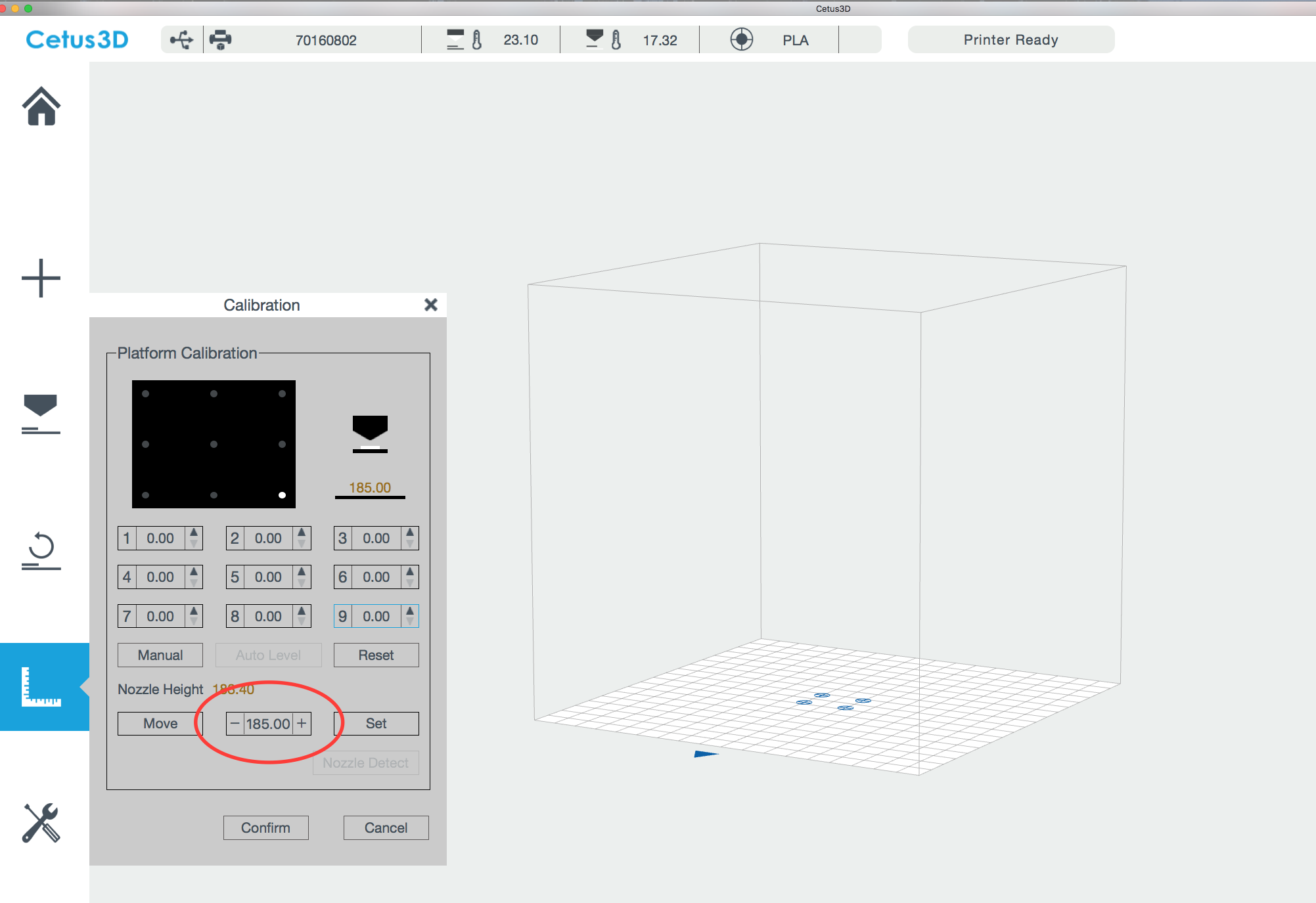

Calibrate cetus3d how to#

For how to set a different nozzle size on your printer, please see HW setup (MK2.5/S & MK3/S/+).Įxcept for the presets for the stock 0.4 nozzle, all other nozzle configurations will have the diameter stated in the name of the profile. You can always do the Wizard again and modify the settings. Unclick all the other models and nozzle diameters to avoid confusing the presets. Note that the E3D V6 0.25 mm nozzle has no dots, and looks almost the same as the E3D compatible 0.4 mm nozzle which ships with the Original Prusa MINI. The E3D 0.4 mm nozzles shipped with the Original Prusa MK3S+ have three dots ( blue arrows). On E3D V6 nozzles, you can identify the nozzle diameter by the dots around the rim of the nozzle. By contrast, if you want to speed up the print and the details are not as important, you can try using the 0.6 or 0.8 mm nozzle. We recommend using it only for very small objects, a few centimeters in size, as the print times are considerably longer compared to 0.4mm nozzles. To achieve fine detail, you can use a 0.25 mm nozzle.

On top of that, you can always create and customize your own profiles. It is also accessible and reasonable to manufacture, which is probably why many 3D printers are supplied with brass nozzle.īesides the standard 0.4 mm diameter, we provide configurations for 0.25 mm, 0.6 mm, and 0. Brass nozzle 0.25/0.4/0.6/0.8īrass has excellent heat conductivity and is tough enough to print most "everyday" filaments. If you need to change or replace the nozzle, please refer to our guide Changing or replacing the nozzle (MK2.5S/MK3S/MK3S+) or Changing/replacing the nozzle (MINI).

0 kommentar(er)

0 kommentar(er)